FumeVac

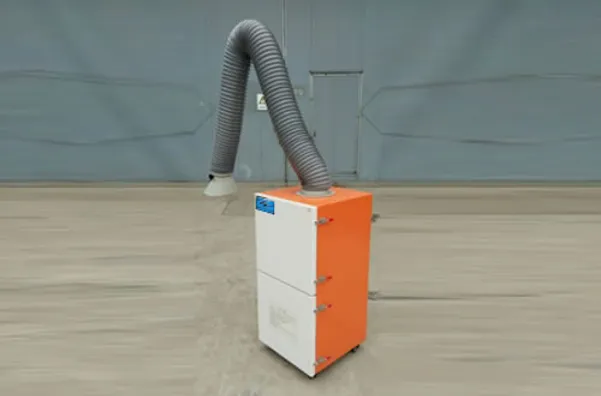

Welding Fume Extractor Vacuums

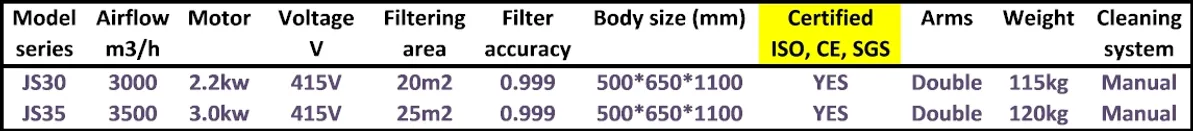

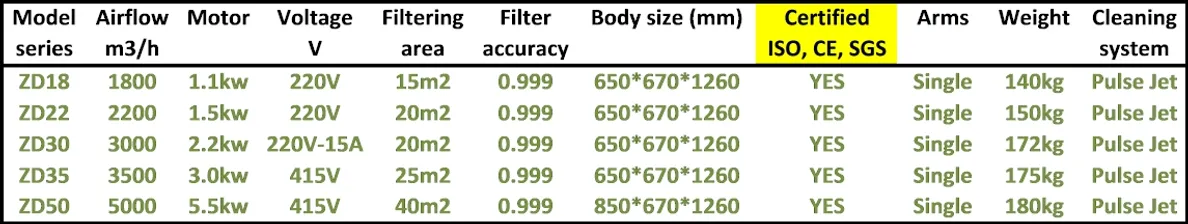

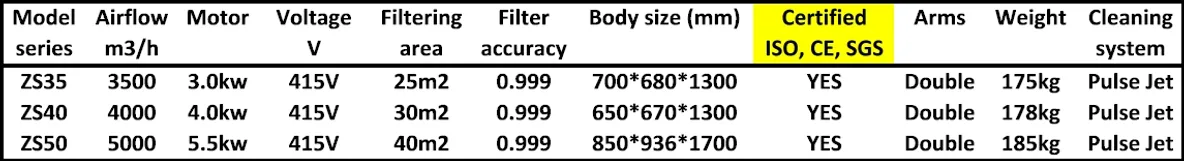

We specialise in servicing the welding industry by providing top quality welding fume extractor vacuums. We supply a range of Single Phase and three phase machines: JS, ZD and ZS series extractor vacuums.

FumeVac extraction equipment operates under the source capture principle. This maximizes the protection to workers by removing welding smoke, welding fumes and laboratory fumes before they get into the operators breathing area.

Our smoke and fume extraction systems are reliable, durable and competitively priced. FumeVac extractor vacuums also meet WorkSafe, Health and Safety standards.

We have the right extraction vacuum unit for you

Worksafe New Zealand

All FumeVac Extractor Vacuums meet Worksafe standards.

Vapours, gas, and other fumes can put workers and the public at risk when inhaled. These fumes can also cause occupational asthma and damage the nervous system.

The work of many different industries, in particular construction and manufacturing, can produce a range of fumes, depending on the worksite.

These include but are not limited to:

- Asphalt

- Diesel fumes

- Fumes from chemicals used (eg, in a manufacturing process).

Exposure to these and other fumes is a serious health risk and can cause serious diseases.

Why FumeVac

Welding can be a dangerous job

Working with high temperatures and flame increase the opportunity of burns to the skin and welder flash to the eyes. However, a much less noticeable but equally dangerous hazard involves welding fume.

Welding fumes are formed when a metal is heated above its boiling point and its vapours condense into very fine, airborne particles that can cause both acute and long term chronic effects to your health, especially when inhaled.

Installing FumeVAc Extraction Equipment

By far one of the most effective and efficient methods of welding fume removal is the incorporation of a fume extractor. Adjustable to your work space, a FumeVac extractor will withdraw and filter out fume at the source, reducing the risk of contamination to the surrounding work area.

Affordable quality products, backed up with exceptional after-sales service.